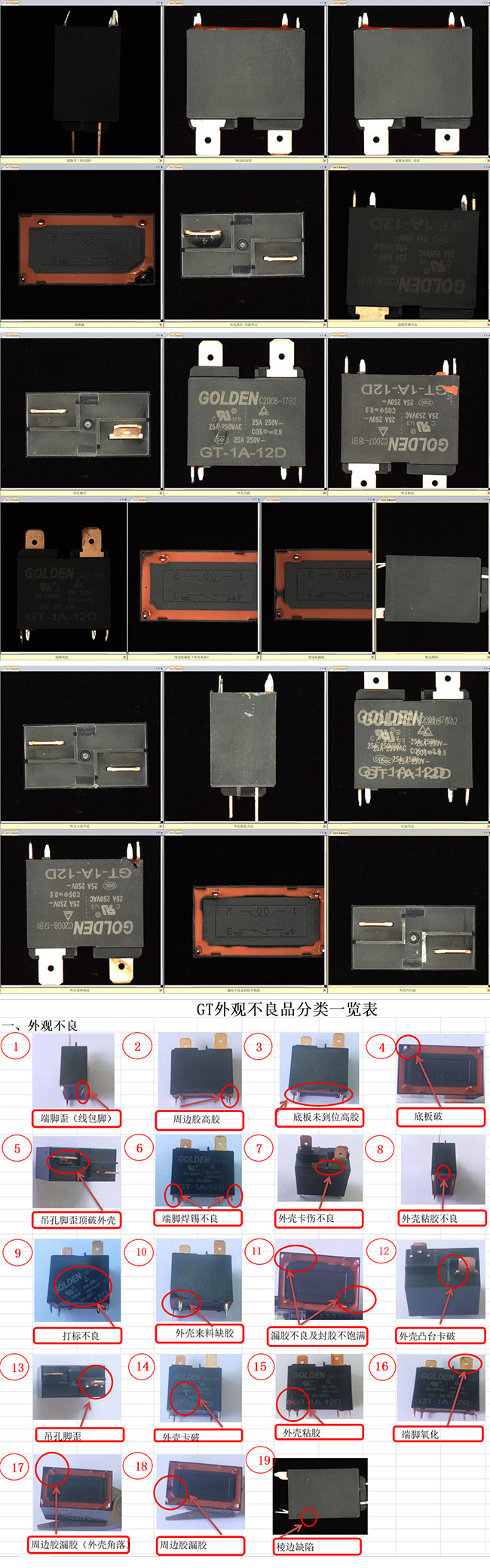

Six sided appearance inspection plan for relays

Detect defect types:

1. Uneven ends (wire wrapped feet)

2. High adhesive around the perimeter

3. Bottom plate not in place and high adhesive

4. Bottom plate broken

5. The lifting hole feet are crooked and the outer shell is broken

6. Poor soldering of the end pins

7. Poor casing jamming

8. Poor adhesion of the outer shell

9. Poor marking

10. Insufficient glue in the incoming shell material

11. Poor glue leakage and insufficient sealing

12. Shell protrusion broken

13. Hanging hole feet are crooked

14. Shell stuck

15. Shell adhesive

16. End oxidation

17. Peripheral glue leakage (corner of shell)

18. Peripheral glue leakage

19. Edge defects

It is necessary to use deep learning algorithms and establish corresponding models for judgment, so a certain number of samples are needed to establish models:

(1) Shell adhesive defects, 20 on each side, a total of 120

(2) The shell is damaged, with 100 pieces on each side, totaling 600 pieces

(3) 200 pieces each with broken outer shell and protruding platform of the hanging hole foot, totaling 100 pieces

(4) There are 20 skewed hanging hole legs, 20 skewed end legs, and 60 high adhesive edges, each for a total of 60

(5) Poor soldering of the end pins and oxidation of the hanging hole pins, 100 each, totaling 200

(6) 300 defects such as insufficient sealing and leakage of adhesive around the bottom plate

(7) 50 defective markings

(8) A total of 1530 NOK samples were used to develop the model, along with 100-200 OK samples.

Summary: This system adopts a feature extraction algorithm based on deep learning. After training with batch samples, combined with traditional algorithms, it can efficiently extract defects on the surface of relays.