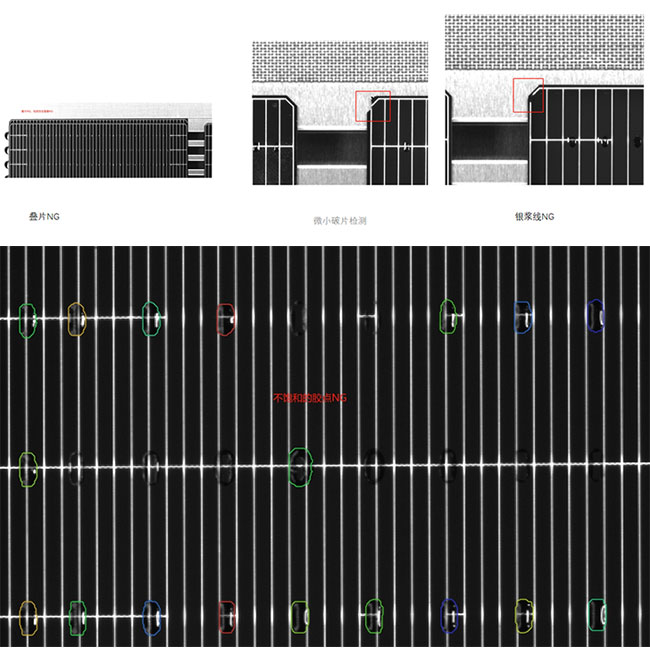

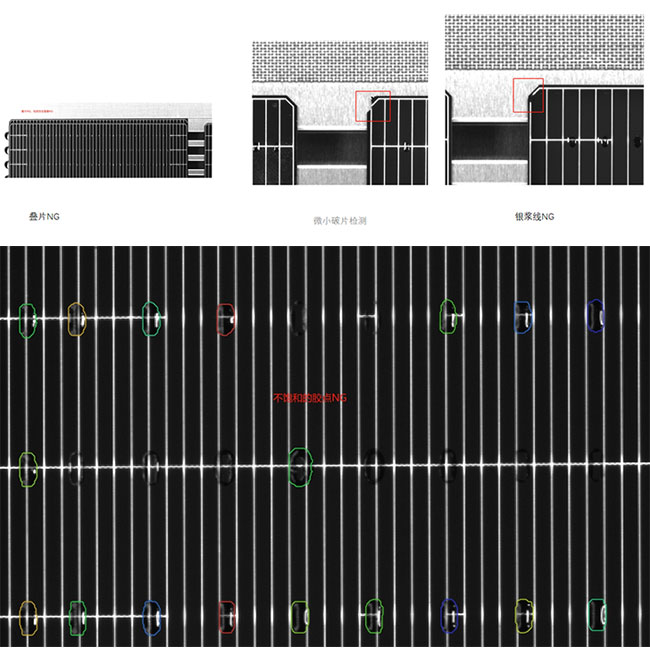

Realize contour analysis, area analysis, and position analysis of hundreds of adhesive points on both sides of the battery cell (based on printing parameters, such as a total of 624 points on 24x26); Simultaneously achieving detection and alarm of battery fragments to avoid residual fragments in the printing position causing subsequent NG; Simultaneously achieve detection of four camera workstations (with a single detection system that can expand the number of detection channels, i.e. the number of camera workstations)< Br/>

Actual on-site rhythm: The single workstation takes 0.4s-0.6s (rhythm can be improved and optimized), and has been running continuously for nearly a year< Br/>

In the laboratory environment simulation (with only a small amount of operation control compared to the actual site), there were no abnormalities during continuous testing for several months. A single camera was tested at approximately 1.175W times per hour, which is a 4-station equipment. Pure visual simulation can reach 4.7W pieces per hour.